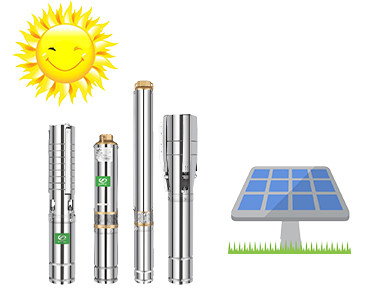

Water For Life With Solar Power

We are not just a manufacturer of solar water pumps, we focus on your business and help you achieve your long-term goals.

- Catalog Of Hot-selling Models

- Free Marketing Guidance

- Free Selection Guidance

- Free Customized Service Plan

2 years warranty, quick response to any quality problems within 24 hours. If your team needs professional training, please contact us for online training.