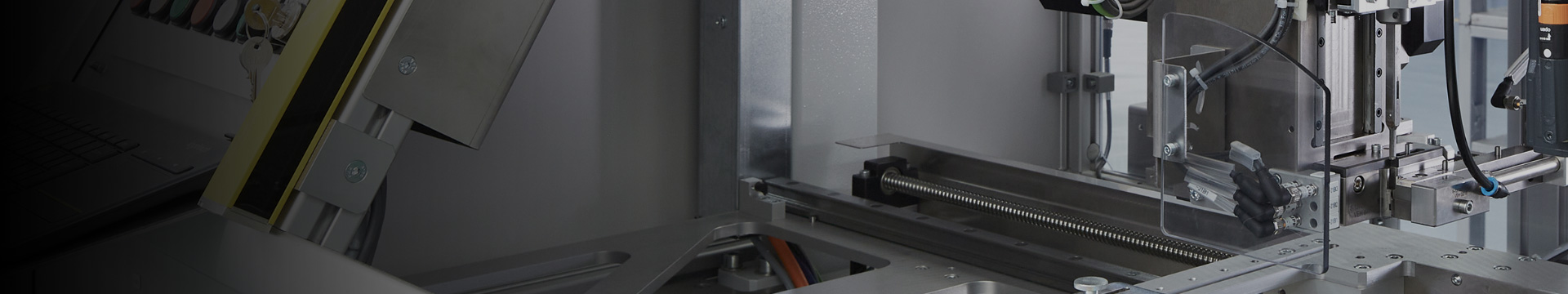

Motor Coil

Wound by automatic wire inserting machine. All enameled wires are made of 180-degree high-temperature wires, and the stators are made of 600 cold-rolled silicon steel sheets.

NO.1-1

NO.1-1Wound by automatic wire inserting machine. All enameled wires are made of 180-degree high-temperature wires, and the stators are made of 600 cold-rolled silicon steel sheets.

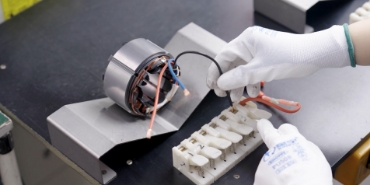

NO.1-2

NO.1-2The coil after processing is subjected to turn-to-turn and withstand voltage tests. Qualified products are dipped in paint to increase the insulation and firmness of the coil.

NO.2

NO.2After being checked by the quality inspector, laser marking is carried out according to the customer's requirements.

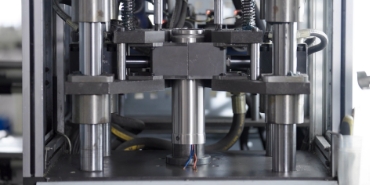

NO.3

NO.3Press-fits the motor circlip cover with fully automatic press-fitting equipment.

NO.4

NO.4Motor coil press-fitting with precise positioning.

NO.5

NO.5The size of each press-fitted motor is measured. After passing the test, the motor can be put into production.

NO.6

NO.6For the welding of the oil cylinder cable and the lead wire of the motor coil, double-walled tubes are used to protect the welding point with insulation.

NO.7

NO.7The rotor adopts 304 stainless steel shaft, which avoids the risk of broken shaft. The magnet is made of 40SH aluminum iron boron material, and the temperature resistance can reach 150 ℃.

NO.8

NO.8The mechanical seal is made of silicon carbide impregnated with graphite, and the sealing performance of the motor is stronger.

NO.9

NO.9After the oil cylinder is press-fitted, the sealed semi-finished motor is completed

NO.10

NO.10The installed motor will undergo power-on test and air tightness test to ensure the tightness and stability of the motor.

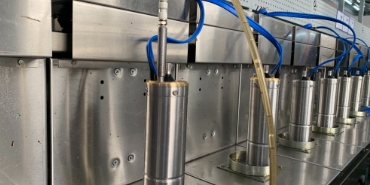

NO.11

NO.11After passing the inspection, the motor is vacuum filled with lubricating oil, and a high-quality motor is completed.

DIFFUL solved the problem of domestic water supply for me. The water pump I used only needs a 200w solar panel, which can satisfy the water supply of our whole family.

The quality of the water pump is very good, and the delivery is very timely. They track the transportation status of the goods actively and give us timely feedback. The water pump is now running very well.

Used to replace the previous electric pump. The water pump works with three 330w solar panels for a 60m deep well. The water pump works very well, even on cloudy days.

We are famous for our professional services and solutions. Please contact us to let us know what you need and what problems you want to solve. We will provide the best solutions for your needs.